Week7

Week 7¶

Computer Controlled Machining

Design something big IN PAIRS! . You can use up to a maximun of half full board ( that means 1200x1200mm) of the available material per student. 15 mm thick pine plywood boards. You will cut your design with your teammate, so you will cut the whole panel at once.

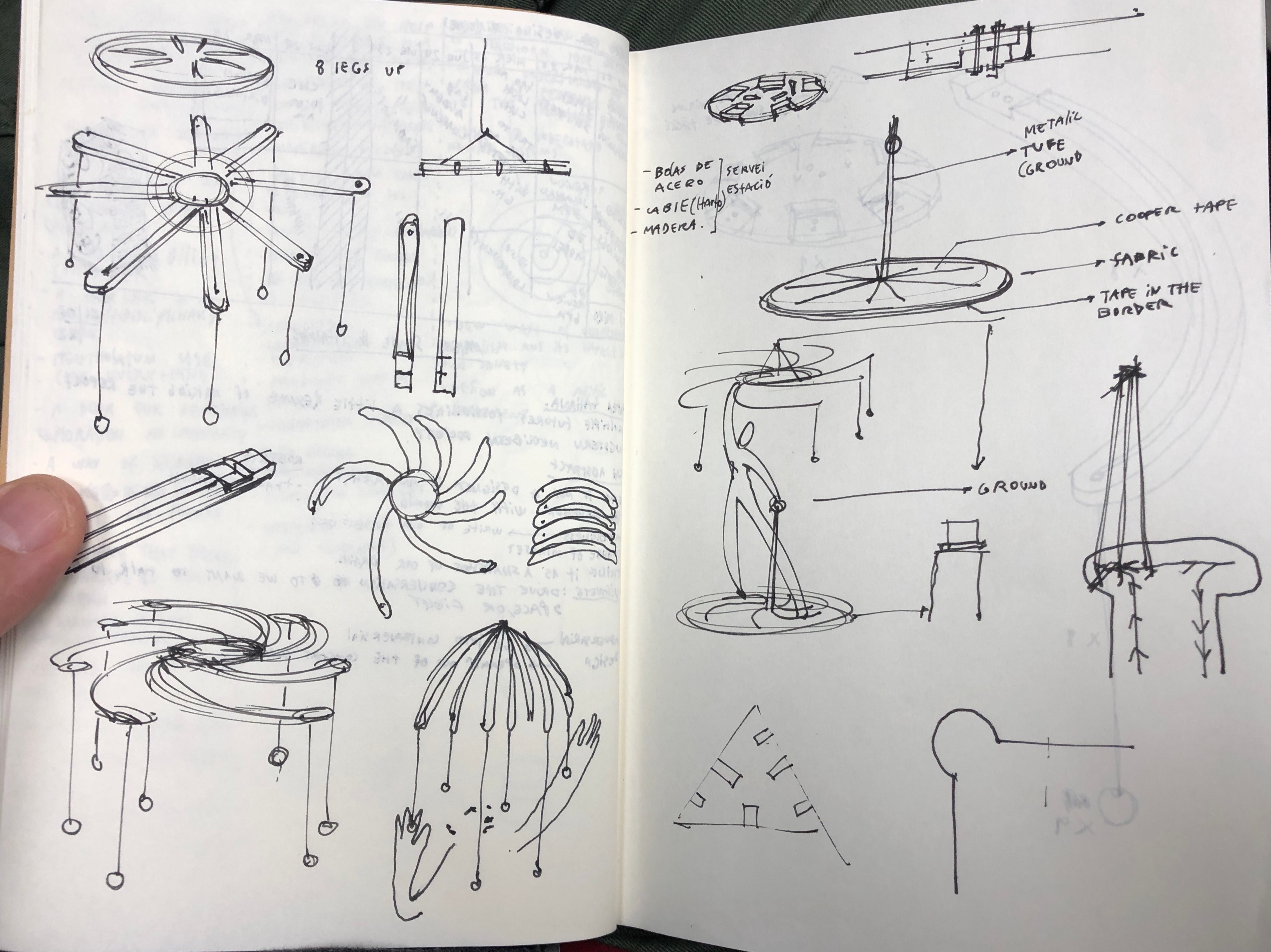

For this week, I chose to use the design dialogues instance to make a file to be cutted by CNC, The object is a holder for steel balls, that would work as an instrument controlled by a playtronica board

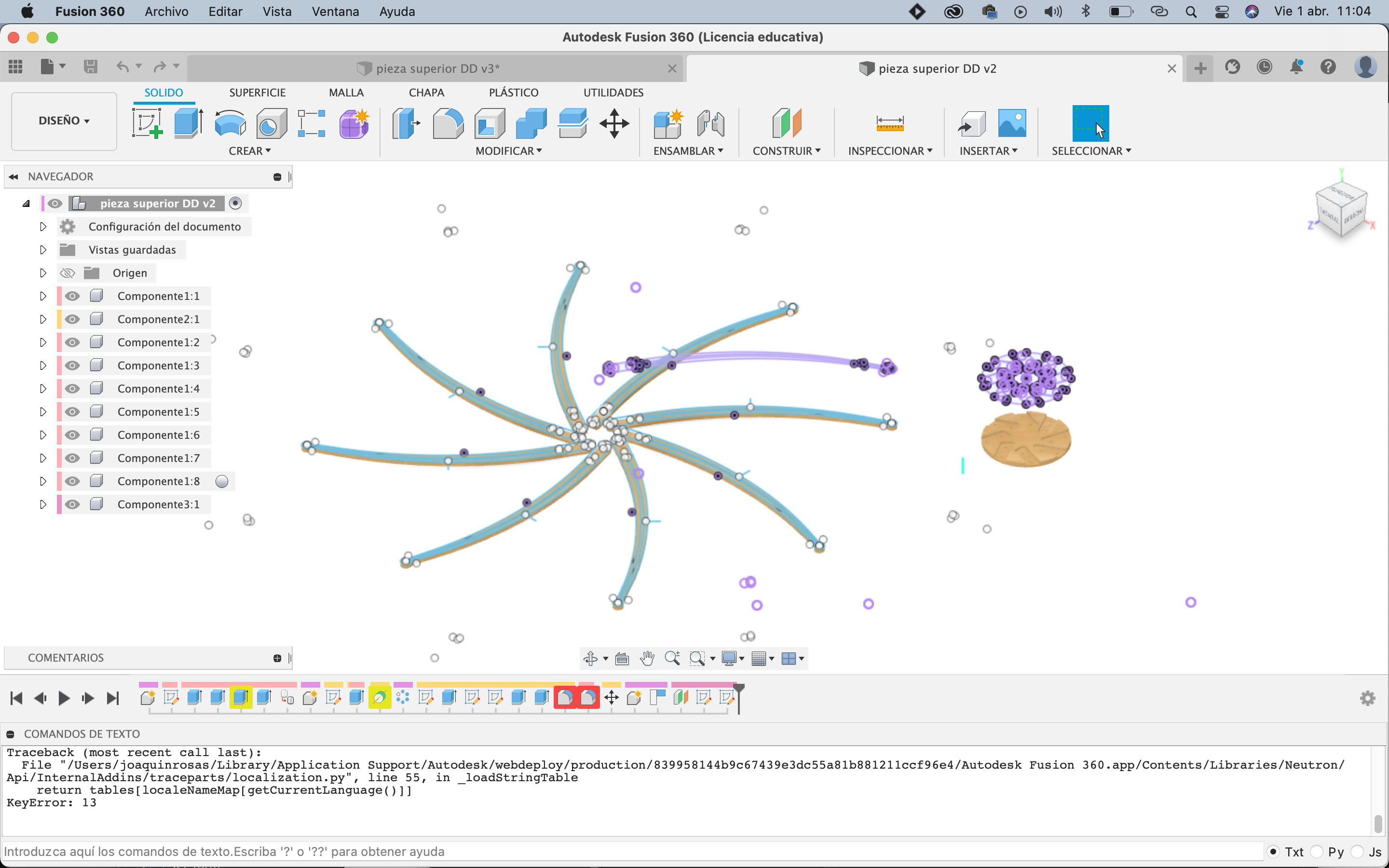

After measurign the space, I made the 3d file in Fusion 360. It has 8 arms and a central piece to fit the arms. Also the arms have a pocket to fit the cable wire.

Then I exported the blueprint of the file into a dxf file, to program the CAM cut in rhino Cam

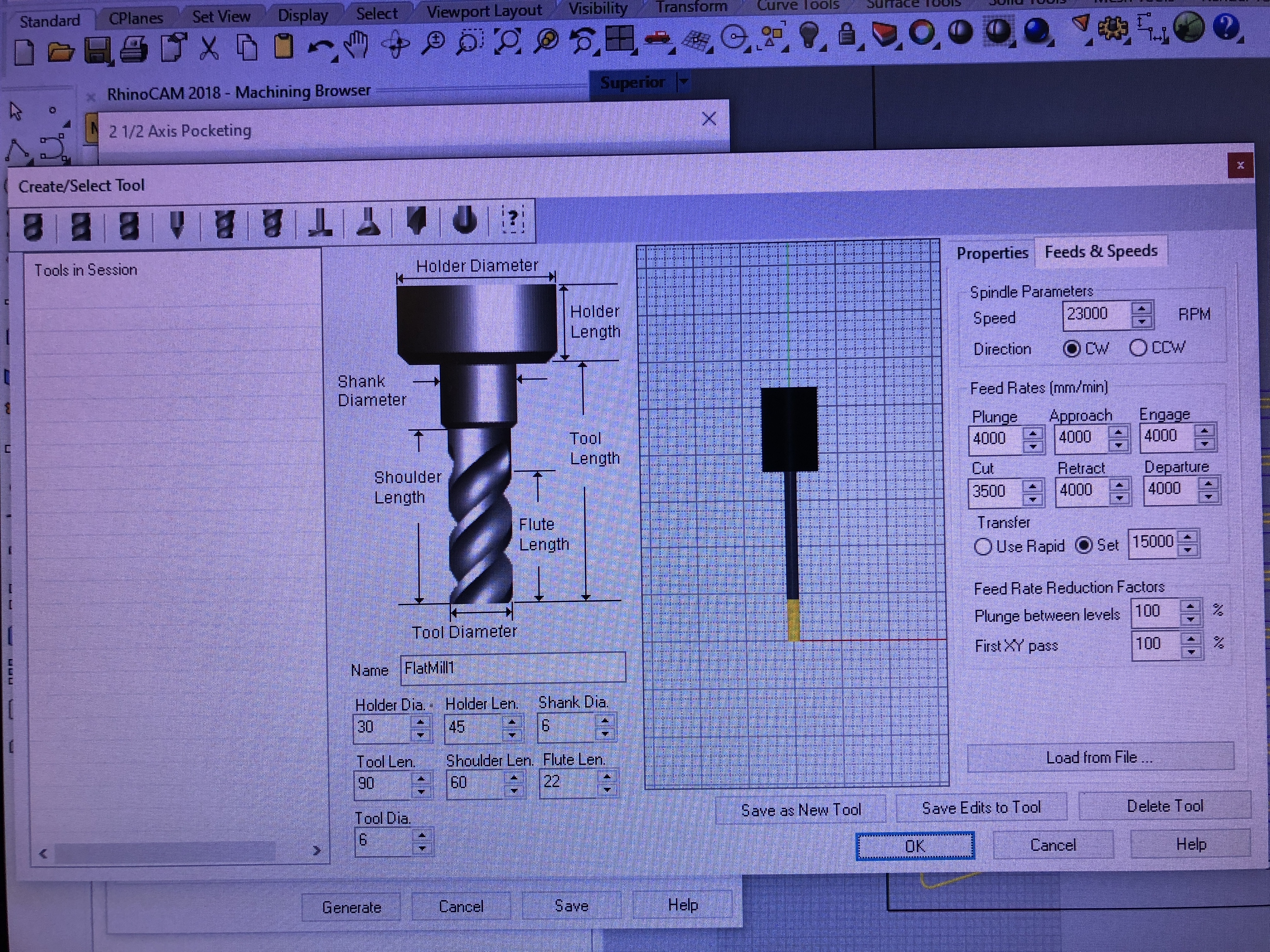

Its necesary to write down the feeds and speed on this machine.Also that parameters change as its cutting different materials, or changing the tool.

After programing everything, its necesary to setup the zero of the machine in relation to the material that its going to be cutted. I used 15mm plywood to make the cut.

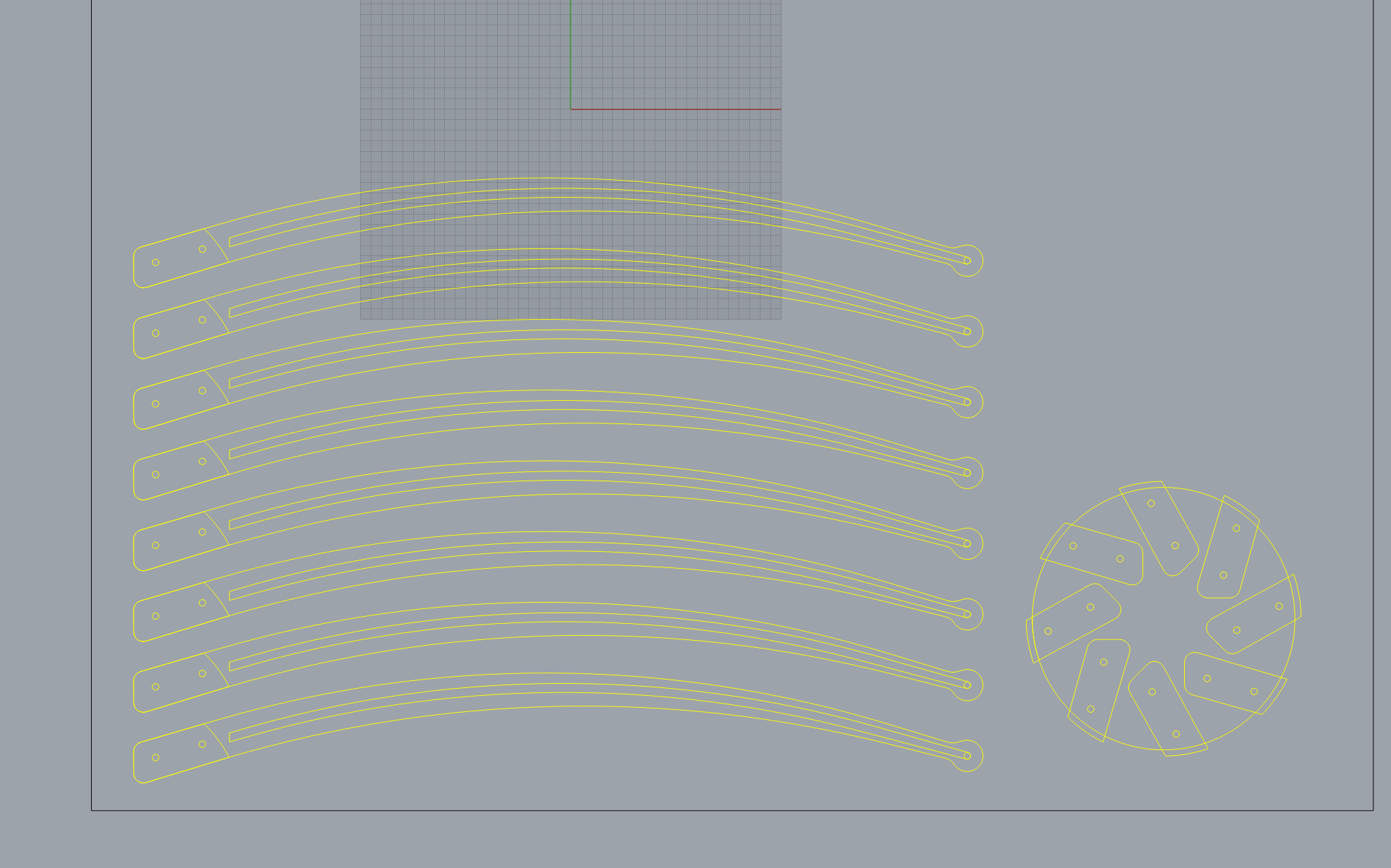

The pocketings were much faster than I expected, It has to start with the inside cuts, to continue with the holes and the exterior profiling.

The Cam process was:

1.- Driling holes for screws 2.-Pocketing 3.-Inside profiling 4.- Outside profiling with tabs

After cutting, the parts were assembled with bolts, to ensure that it will not fall apart, because there its going to be more weight hanging from the structure

The structure is installed and ready tu use. It was necesary to add more strings to ensure that it keep its steady in the air.

It was very interesting that as the bolts where magnetic, they were used to attach the cables to make the connection, It worked very well.